Product Description

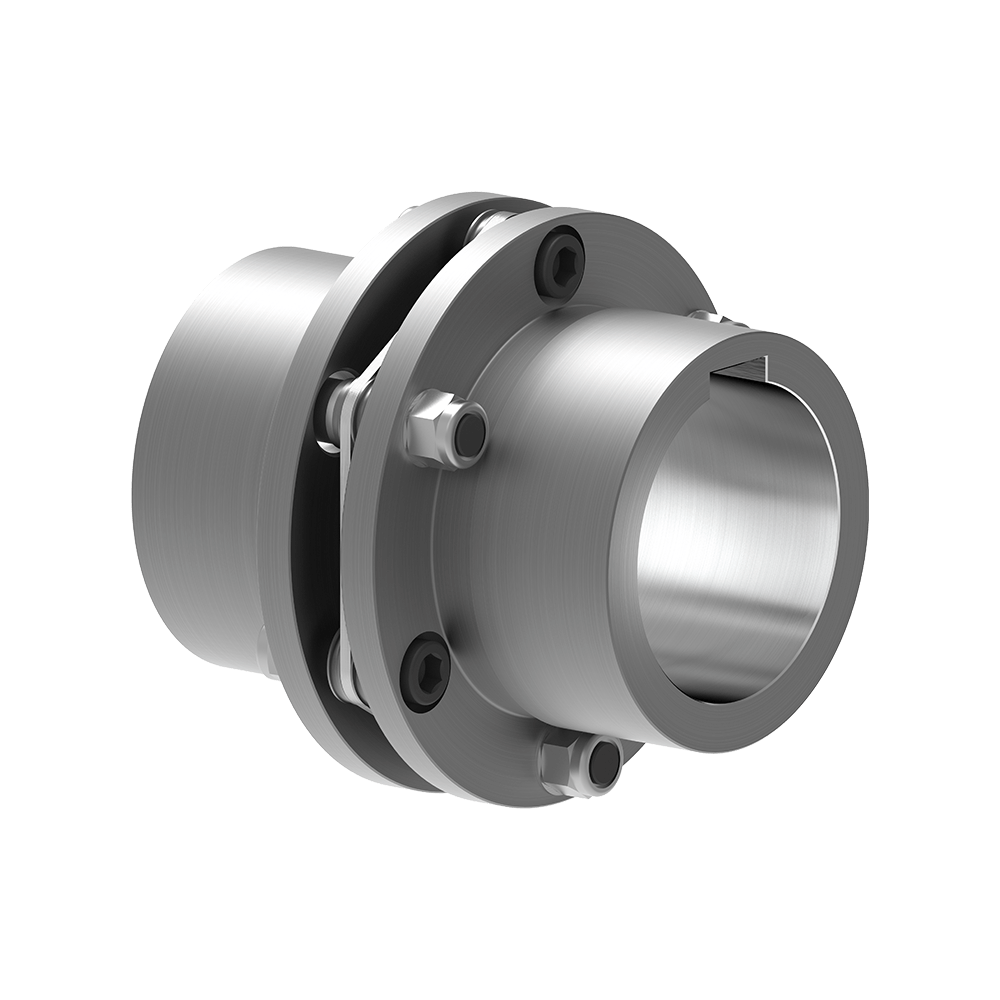

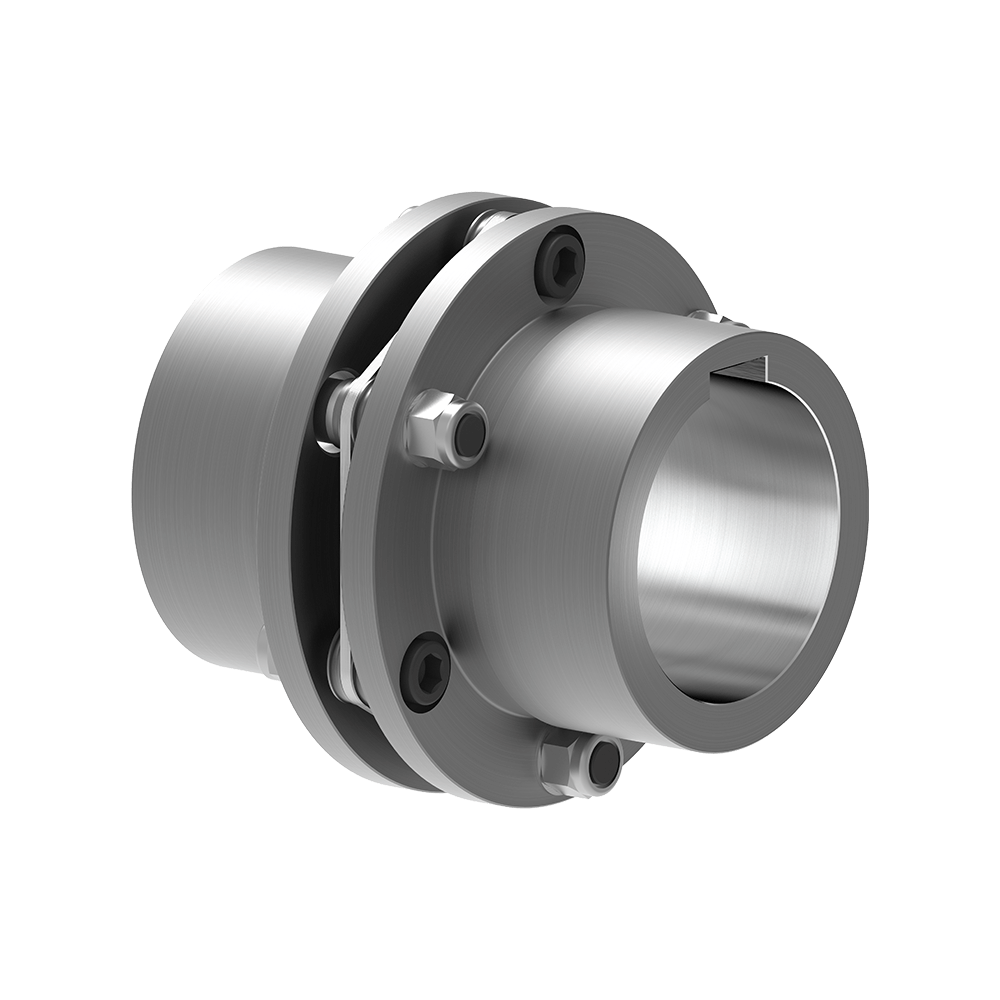

CNC Machined Parts Precision Metal Parts Motorcycle Parts

Product Description

1. Precision CNC machining parts strictly follow customers’ drawing, packing, and quality requirements.

2. Tolerance: between+/-0.01mm;

3. The high-tech CMM inspector to ensure the quality;

4. Full-Experienced engineers and well professional trained workers;

5. Fast delivery time;

6. Professional advice for our customers;

Detailed Photos

Product Parameters

Our advantage of cnc machining:

| Business Type | Beyond the Manufacturer and strong organized ability in the industrial |

| Benefits | 1. Deeper industrial experience at CNC machining parts service for more than 10-years,our customer’s requirement is our 1st priority. 2. 2D or 3D files is available; 3. We trust the quality priority and we insist the good quality should be based on the customers’ satisfied; 4. Without any MOQ requirement; 5.Faster delivery time; 6. Customized size and specification /OEM available 7. Near ZheJiang Port |

The material

| Materials Accept |

Stainless Steel | SS201, SS303, SS304, SS316 etc. |

| Steel | Q235, 20#, 45#, | |

| Brass | C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37) , C28000(CuZn40) | |

| Iron | 1213, 12L14,1215 etc. | |

| Bronze | C51000, C52100, C54400, etc. | |

| Aluminum | Al6061, Al6063,AL7075,AL5052 etc | |

| Plastic | ABS,POM,PC(Poly-Carbonate),PC+GF,PA(nylon),PA+GF, PMMA(acrylic)PEEK,PEI etc) |

Packaging & Shipping

- We prefer DHL or TNT express or other air freight between 1kg-100kg.

- we prefer sea freight more than 100kg or more than 1CBM

- As per customized specifications.

Company Profile

About us

HangZhou CHINAMFG Technology Co.,Ltd is located in HangZhou City, ZheJiang Province, Which closed the ZheJiang .The Emitech Technology is mainly engaged in the CNC Machinery Industrial Service for 15 years. Our Parts are sold to Europe, America, Japan, South Korea and China in various kinds of industrial.At present, Our company has CNC Turning machines and CNC centers and equip with professional quality and testing instruments.We have full OEM Experience from worldwide, providing them with One-stop solutions for a broad range of applications.We look CHINAMFG to cooperating with you!

Our Advantages

1. Precision CNC machining parts strictly follow customer’s drawing,packing and quality requirement.

2. Tolerance: between+/-0.01mm;

3. The high-tech CMM inspector to ensure the quality;

4. Full-Experienced engineers and well professional trained workers;

5. Fast delivery time;

6. Professional advice for our customers;

After Sales Service

Factory Supply High Demand aluminum machining parts factory

We usually provide 12 Months repair service. If our duty, we will respond to send the new parts.

Our Service

| Our Processing | CNC center, CNC milling, CNC turning, drilling, grinding, bending, stamping, tapping, |

| Surface finish | Polishing, sandblasting, Zinc-plated, nickel-plated, chrome-plated, silver-plated, gold-plated, imitation gold-plated, |

| Tolerance | 0.05mm~0.1mm |

| QC System | 100% inspection before shipment |

| Drawing format | CAD / PDF/ DWG/ IGS/ STEP |

| Packaging | Plastic bag/Standard package / Carton or Pallet / As per customized specifications |

| Payment Terms | 30 -50%T/T in advance, 70-50% balance before delivery; Pay Pal or Western Union is acceptable. |

| Trade terms | EXW, FOB, CIF, As per the customer’s request |

| Shipment Terms |

1)We prefer DHL or TNT express or other air freight between 1kg-100kg. 2) we prefer sea freight more than 100kg or more than 1CBM |

| Note | The CNC machining parts are usually custom-made based on the customer’s drawings and samples. So we need the Down Payment |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Indicators of Wear or Damage in Disc Couplings

Disc couplings can exhibit signs of wear or damage over time due to factors like misalignment, overloading, or general usage. Detecting these issues early is crucial for preventing further damage. Some common indicators of wear or damage in disc couplings include:

- Vibration: Excessive vibration during operation can signal misalignment, component wear, or imbalance in the disc coupling.

- Noise: Unusual noises like clicking, clanking, or rattling can indicate wear, misalignment, or damage in the coupling components.

- Heat Generation: Excessive heat near the coupling area can suggest friction or misalignment issues.

- Reduced Performance: Decreased efficiency, torque transmission, or system performance may point to coupling wear or damage.

- Visual Inspection: Look for signs of visible wear, corrosion, cracks, or deformation on the coupling components.

To detect these signs of wear or damage, regular visual inspections, vibration analysis, and performance monitoring are essential. Early detection allows for timely maintenance or replacement of the affected components, ensuring the continued reliability and safety of the disc coupling and the machinery it serves.

Suitability of Disc Couplings for High-Speed Rotation and Critical Alignment

Disc couplings are well-suited for applications involving high-speed rotation and critical alignment due to their unique design and performance characteristics:

- High-Speed Rotation: Disc couplings can handle high rotational speeds while maintaining their balance and integrity. Their lightweight and compact design minimize the effects of centrifugal forces, making them suitable for high-speed applications.

- Critical Alignment: Disc couplings offer excellent flexibility and angular misalignment compensation. They can accommodate axial, radial, and angular misalignments, making them suitable for applications where maintaining precise alignment is crucial.

- Torsional Stiffness: Disc couplings can provide a balance between flexibility and torsional stiffness, allowing them to transmit torque accurately even in critical alignment scenarios.

- High Torque Capacity: Many disc couplings are designed to handle high torque loads, making them suitable for applications with demanding torque requirements.

- Resonance Damping: The flexible nature of disc couplings can help dampen vibrations and reduce the risk of resonance, which is important in high-speed applications.

When selecting a disc coupling for high-speed rotation and critical alignment, it’s essential to consider factors such as torque requirements, speed range, misalignment compensation, space limitations, and dynamic behavior to ensure optimal performance and reliability in the specific application.

Considerations for Selecting a Disc Coupling for a Specific Application

Choosing the right disc coupling for a particular application involves considering several important factors to ensure optimal performance and reliability:

- Torque Requirements: Determine the maximum and continuous torque requirements of the application. Select a disc coupling that can handle the expected torque without exceeding its rated capacity.

- Misalignment: Evaluate the type and magnitude of misalignment expected in the system, including angular, parallel, and axial misalignment. Choose a disc coupling with the appropriate misalignment capability to accommodate these factors.

- Speed and RPM: Consider the operating speed and rotational speed of the connected shafts. High-speed applications may require disc couplings with balanced design to prevent vibration issues.

- Space Limitations: Evaluate the available space for installing the coupling. Disc couplings are compact and can be suitable for applications with limited space.

- Environmental Conditions: Assess the operating environment, including temperature, humidity, presence of corrosive agents, and exposure to dust or debris. Choose materials and coatings that can withstand the environmental conditions.

- Shaft Sizes: Ensure that the disc coupling’s hub bore sizes match the shaft sizes of the connected equipment.

- Alignment Maintenance: Consider the ease of installation and alignment maintenance. Some disc couplings feature spacer elements that simplify alignment and reduce downtime during maintenance.

- Backlash: Evaluate the backlash or play that the coupling introduces between the shafts. Backlash can affect the accuracy of position and torque transmission in precision applications.

- Dynamic Balancing: For high-speed applications, consider disc couplings that are dynamically balanced to prevent vibration issues that can arise from rotational imbalance.

- Resonance and Damping: Determine if the coupling design includes features to dampen vibrations and reduce the risk of resonance in the system.

- Service Life: Estimate the expected service life based on the application’s duty cycle and requirements. Choose a disc coupling with a suitable service life to avoid frequent replacements.

- Cost and Value: Compare the cost of the disc coupling with its features, performance benefits, and expected lifespan. Choose a coupling that provides the best value for your specific application.

By carefully considering these factors, you can select a disc coupling that meets the unique requirements of your machinery system and ensures reliable operation.

editor by CX 2024-05-09