Product Description

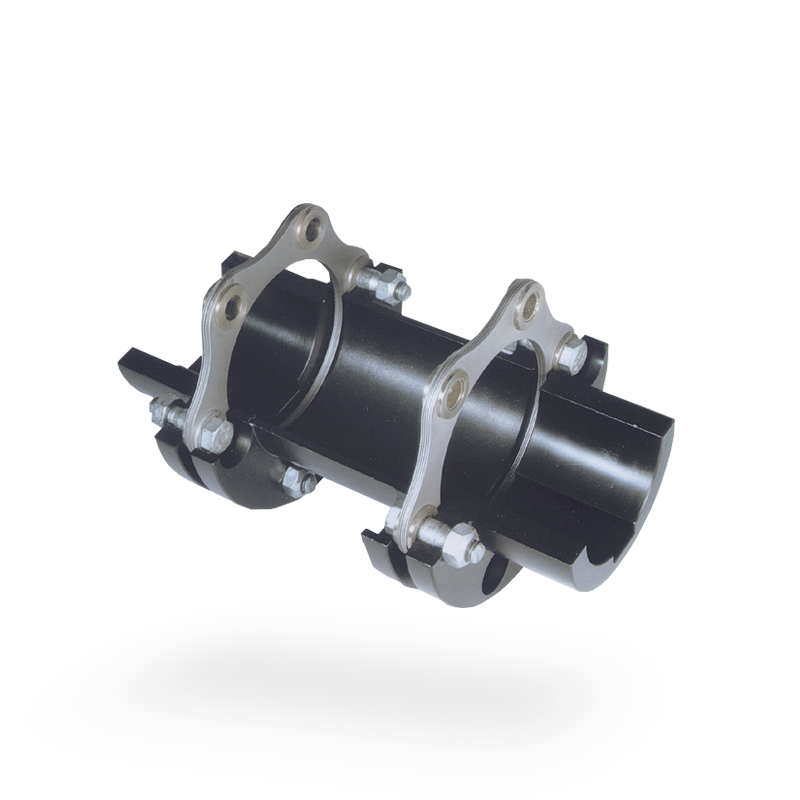

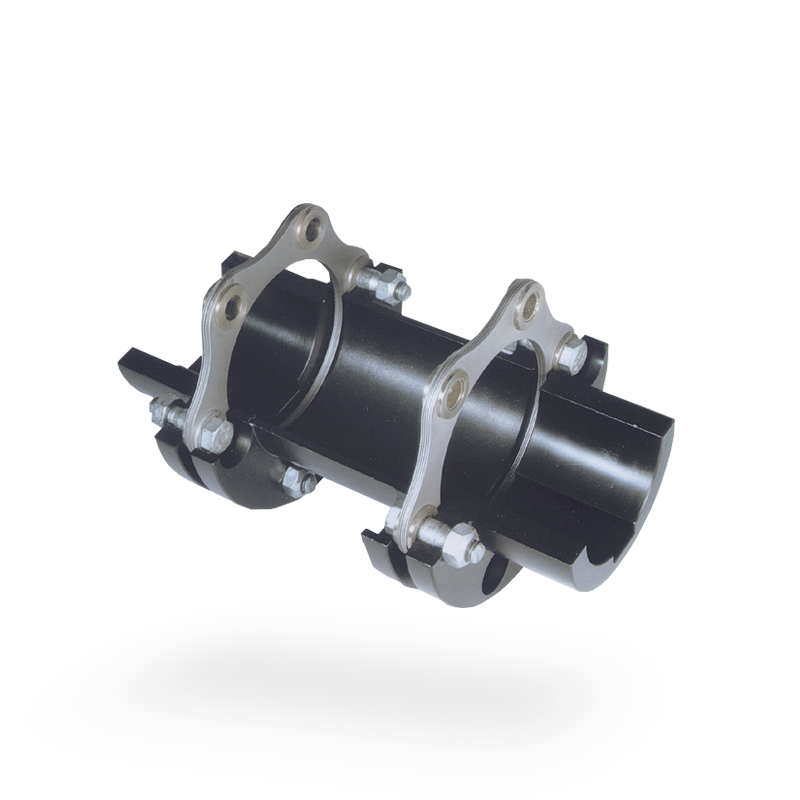

Torsionally rigid high torque CHINAMFG customized single elastic spacer stainless steel flexible drum disc shaft gear coupling for crane

Metal flex couplings are disc type couplings in which several flexible metallic elements are alternately attached with bolts to opposite flanges. As polymeric elastomer is replaced by metal disc, Metal Flex coupling provides excellent temperature capability without sacrificing angular and axial misalignment. The coupling provides low axial and bending stiffness while possessing high torsional rigidity. The stretched shim pack design of CHINAMFG Metal Flex couplings provides zero backlash. CHINAMFG Metal Flex couplings are available up to 13367 Nm torque with single shim pack (UMK) and double shim pack (UMS) series.

FEATURES

1.Power to weight ratio high

2.Accommodates angular and axial misalignments

3.High temperature application

4.Visual inspection is possible without dismantling equipments

5.Low axial stiffness with high torsional rigidity

6.High-speed capacity

7.Range up to 12000 Nm

8.Added advantage of stretch fitted shim pack

|

Material Available |

Stainless Steel:SS201,SS301, SS303, SS304, SS316, SS416 etc. |

|

CNC Turning |

φ0.5 – φ300 * 750 mm,+/-0.005 mm |

|

CNC Milling |

510 * 1571 * 500 mm(max),+/-0.001 mm-+/-0.005 mm |

|

Surface Finish |

Aluminum:Clear Anodized,Color Anodized,Sandblast Anodized,Chemical Film,Brushing,Polishing,Chroming. |

|

Drawing Format |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

Test Equipment |

Measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. |

Production workshop:

Manufacturer of Couplings, Fluid Coupling, JAW Coupling, can interchange and replacement of lovejoy coupling and so on.

A coupling can interchange and replacement of lovejoy coupling is a device used to connect 2 shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join 2 pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

Company information:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Industry Standards and Guidelines for Disc Couplings

Disc couplings, like other mechanical components, are subject to various industry standards and guidelines that ensure their safe and reliable operation. Some relevant standards include:

- API Standard 671: This American Petroleum Institute (API) standard provides guidelines for special-purpose couplings for use in petroleum, chemical, and gas industry services. It covers the design, materials, testing, and inspection of couplings, including disc couplings.

- AGMA Standard 9001: The American Gear Manufacturers Association (AGMA) standard 9001 addresses flexible couplings, including disc couplings, and provides recommendations for their design, installation, and maintenance.

- ISO 14691: This International Organization for Standardization (ISO) standard covers general-purpose industrial couplings, including disc couplings, and provides guidance on their selection, installation, and operation.

Manufacturers and engineers often refer to these standards and guidelines to ensure that disc couplings are designed, manufactured, and used according to recognized industry practices. Adhering to these standards helps enhance the reliability, safety, and performance of disc couplings in various industrial applications.

Recent Advancements in Disc Coupling Design

Disc coupling technology has seen continuous advancements to enhance performance, reliability, and adaptability to various applications. Some recent innovations in disc coupling design include:

- Material Enhancements: The development of new materials, such as advanced alloys and composite materials, has improved coupling durability, corrosion resistance, and overall lifespan.

- Flexible Disc Profiles: Innovative disc profiles are designed to optimize flexibility while maintaining torque transmission capabilities, allowing for better misalignment compensation and shock absorption.

- Modular Designs: Modular disc coupling systems offer flexibility in adapting to different torque and misalignment requirements, making them versatile for a wide range of applications.

- Enhanced Torsional Stiffness: Some designs focus on achieving higher torsional stiffness, ensuring accurate torque transmission and responsiveness even in demanding conditions.

- Smart Couplings: Integration of sensor technology enables real-time monitoring of coupling performance, allowing for predictive maintenance and reducing downtime.

These advancements are driven by the increasing demands of modern machinery and the need for higher efficiency, reduced maintenance, and improved overall system performance. Engineers and manufacturers are continually exploring new ways to optimize disc coupling design for a variety of industries and applications.

Design of Disc Couplings for Flexibility and Performance

The design of disc couplings plays a crucial role in providing flexibility and ensuring high-performance torque transmission. Key design elements include:

- Flexibility: Disc couplings consist of multiple thin metal discs arranged in a pack. These discs have slots or cuts that create segments, allowing them to flex and accommodate misalignment. The flexing action provides flexibility in multiple directions, allowing the coupling to handle angular, parallel, and axial misalignment.

- Torsional Stiffness: While providing flexibility, disc couplings also maintain a certain degree of torsional stiffness. This stiffness ensures efficient torque transmission between the shafts and helps maintain accurate positioning in precision applications.

- Material Selection: High-quality materials with appropriate mechanical properties are used to manufacture the discs. These materials must balance flexibility, torsional stiffness, and strength. Stainless steel and other alloys are commonly chosen for their durability and resilience.

- Geometry and Slot Patterns: The design of the slots or cuts in the discs influences the coupling’s flexibility and misalignment capabilities. Engineers optimize the geometry to provide the desired levels of flexibility and torsional stiffness.

- Spacer Elements: Some disc couplings include spacer elements between the discs. These spacers contribute to accurate alignment between the shafts and help prevent edge contact between the discs, reducing wear and enhancing durability.

- Balancing: Balancing the disc coupling reduces vibration and rotational imbalance. Precision machining and balancing techniques ensure that the coupling operates smoothly at various speeds, minimizing stress on the connected machinery.

- Anti-Flailing Designs: In the event of a disc failure, anti-flailing designs prevent the discs from dislodging and causing damage to surrounding equipment or posing a safety hazard.

The combination of these design aspects results in a disc coupling that can handle misalignment, transmit torque efficiently, dampen vibrations, and maintain its performance over a wide range of operating conditions. The flexible yet robust design makes disc couplings suitable for various industrial applications.

editor by CX 2024-05-08