Product Description

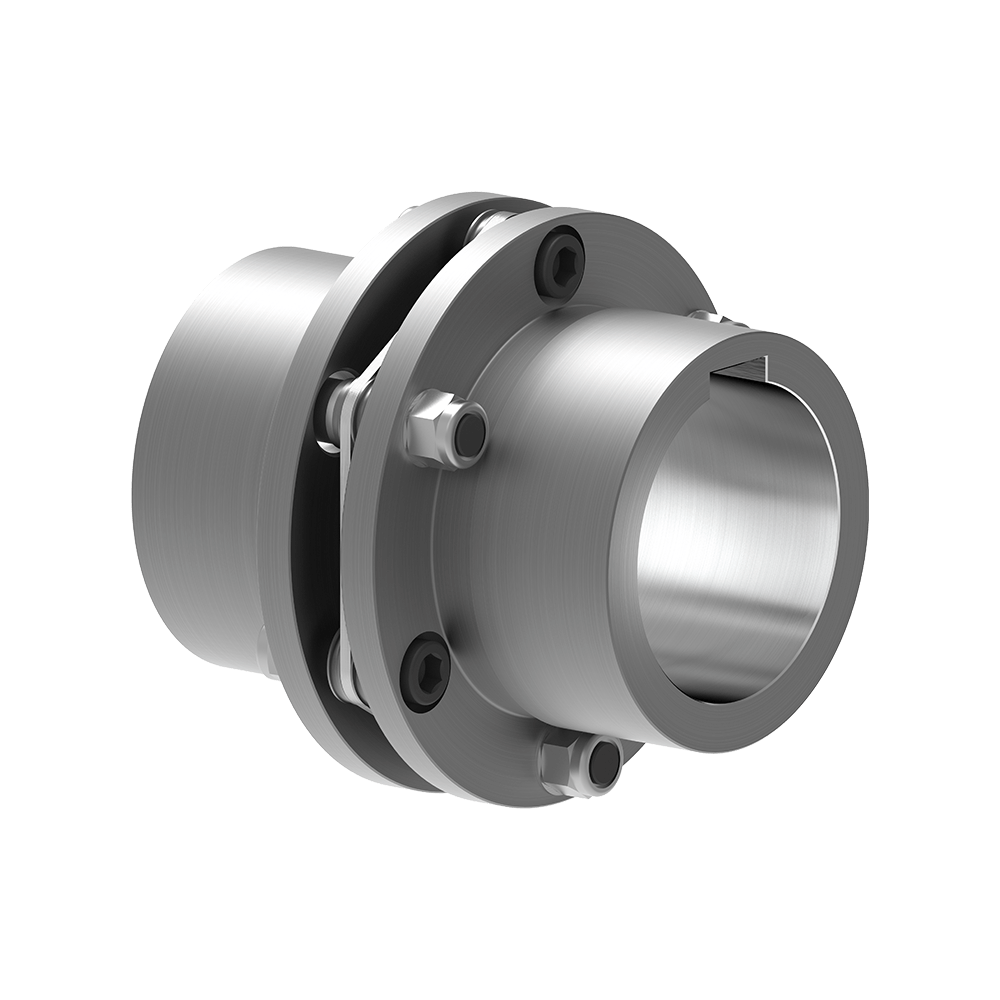

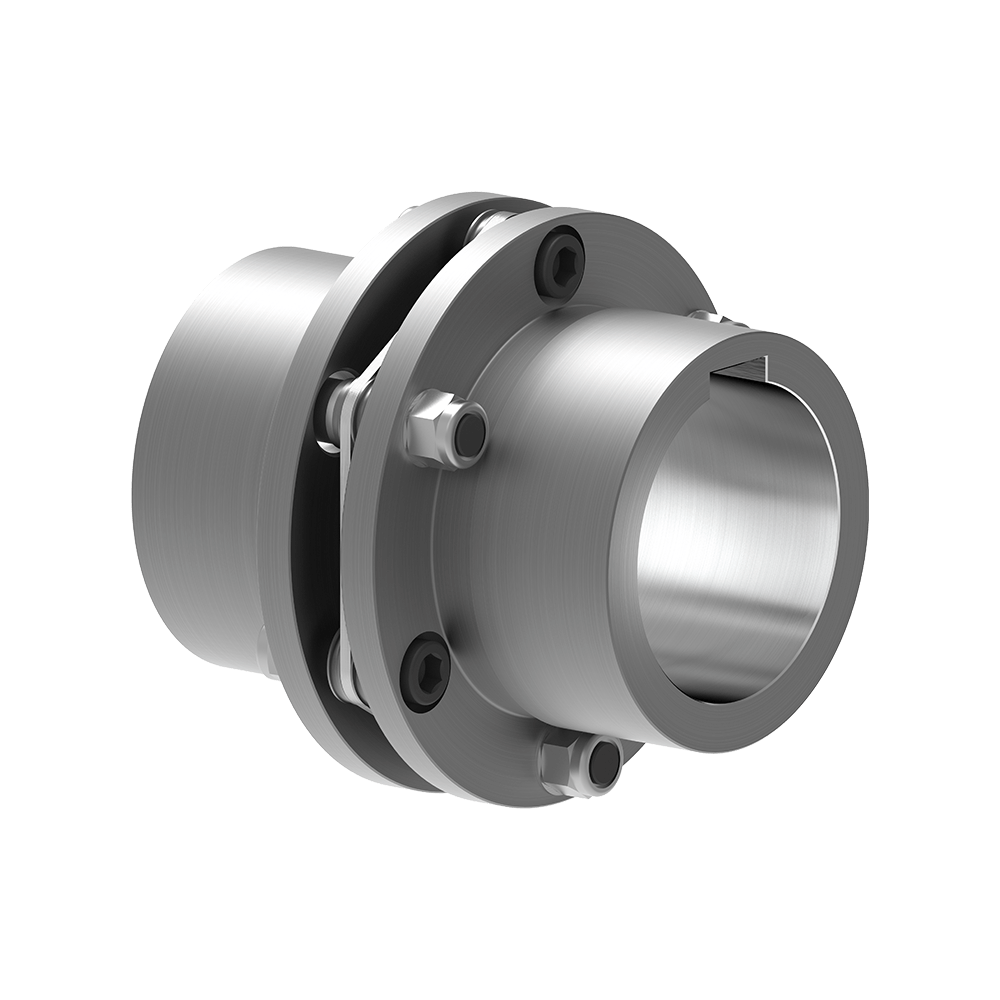

SG7-8 Single plate springs clamp type flexible disc couplings

Product Description

| Item No.: |

|

|||||||

| Features: |

|

|||||||

| Specification: |

|

|||||||

| Application: |

|

|||||||

| Delivery: |

|

|||||||

| Remark: |

|

|||||||

Product Picture

Drawing:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Indicators of Wear or Damage in Disc Couplings

Disc couplings can exhibit signs of wear or damage over time due to factors like misalignment, overloading, or general usage. Detecting these issues early is crucial for preventing further damage. Some common indicators of wear or damage in disc couplings include:

- Vibration: Excessive vibration during operation can signal misalignment, component wear, or imbalance in the disc coupling.

- Noise: Unusual noises like clicking, clanking, or rattling can indicate wear, misalignment, or damage in the coupling components.

- Heat Generation: Excessive heat near the coupling area can suggest friction or misalignment issues.

- Reduced Performance: Decreased efficiency, torque transmission, or system performance may point to coupling wear or damage.

- Visual Inspection: Look for signs of visible wear, corrosion, cracks, or deformation on the coupling components.

To detect these signs of wear or damage, regular visual inspections, vibration analysis, and performance monitoring are essential. Early detection allows for timely maintenance or replacement of the affected components, ensuring the continued reliability and safety of the disc coupling and the machinery it serves.

Customization of Disc Couplings for Specific Machinery Requirements

Disc couplings can indeed be customized to match specific machinery requirements and limitations:

- Size and Configuration: Disc couplings can be tailored in terms of size and disc configuration to accommodate space restrictions and torsional load demands.

- Material Selection: The choice of materials for the disc packs can be customized to ensure compatibility with the operational environment, such as temperature, corrosion resistance, and other factors.

- Performance Parameters: Disc couplings can be designed to meet specific performance parameters, including torque capacity, misalignment accommodation, and torsional stiffness.

- Attachment and Hub Designs: The attachment mechanisms and hub designs can be customized to seamlessly integrate with the existing machinery components.

- Specialized Applications: Manufacturers can create disc couplings with unique features for specialized applications, such as those requiring higher precision, critical alignment, or specific levels of vibration dampening.

Through customization, disc couplings can effectively address the unique requirements and limitations of various machinery systems, enhancing their performance and reliability.

Considerations for Selecting a Disc Coupling for a Specific Application

Choosing the right disc coupling for a particular application involves considering several important factors to ensure optimal performance and reliability:

- Torque Requirements: Determine the maximum and continuous torque requirements of the application. Select a disc coupling that can handle the expected torque without exceeding its rated capacity.

- Misalignment: Evaluate the type and magnitude of misalignment expected in the system, including angular, parallel, and axial misalignment. Choose a disc coupling with the appropriate misalignment capability to accommodate these factors.

- Speed and RPM: Consider the operating speed and rotational speed of the connected shafts. High-speed applications may require disc couplings with balanced design to prevent vibration issues.

- Space Limitations: Evaluate the available space for installing the coupling. Disc couplings are compact and can be suitable for applications with limited space.

- Environmental Conditions: Assess the operating environment, including temperature, humidity, presence of corrosive agents, and exposure to dust or debris. Choose materials and coatings that can withstand the environmental conditions.

- Shaft Sizes: Ensure that the disc coupling’s hub bore sizes match the shaft sizes of the connected equipment.

- Alignment Maintenance: Consider the ease of installation and alignment maintenance. Some disc couplings feature spacer elements that simplify alignment and reduce downtime during maintenance.

- Backlash: Evaluate the backlash or play that the coupling introduces between the shafts. Backlash can affect the accuracy of position and torque transmission in precision applications.

- Dynamic Balancing: For high-speed applications, consider disc couplings that are dynamically balanced to prevent vibration issues that can arise from rotational imbalance.

- Resonance and Damping: Determine if the coupling design includes features to dampen vibrations and reduce the risk of resonance in the system.

- Service Life: Estimate the expected service life based on the application’s duty cycle and requirements. Choose a disc coupling with a suitable service life to avoid frequent replacements.

- Cost and Value: Compare the cost of the disc coupling with its features, performance benefits, and expected lifespan. Choose a coupling that provides the best value for your specific application.

By carefully considering these factors, you can select a disc coupling that meets the unique requirements of your machinery system and ensures reliable operation.

editor by CX 2024-05-07